MakerRoo: What We've Been Working On

If you’re reading this, you probably signed up because you saw the smart light switch replacement PCB project and thought “yes, finally.” Thanks for being here.

This is the first proper update, so let me tell you where things stand.

What is SwitchRoo?

Quick recap for anyone landing fresh: SwitchRoo is a drop-in replacement PCB for Australian smart light switches (starting with Deta). It brings ESP32-C series chips for future Zigbee/Thread support, optional mmWave radar presence detection, and RGB LEDs on each button - all running locally on ESPHome.

No more always-on blue LEDs. No cloud dependency. Full Home Assistant integration with proper local control and the customisation the HA community actually wants. Want your button LEDs to show a state machine or indicate which rooms have lights on? You can do that.

The project grew out of this Home Assistant community thread - now it’s becoming a proper product.

Oh, and it has a name now: SwitchRoo. Because it’s a switch, and you’re switching out the PCB. The -Roo ties into Makerroo, and I liked the double meaning.

Current Progress

First PCB is made. Not populated yet, but the board exists. It’s real. I’ll share more photos once I’ve got components on it.

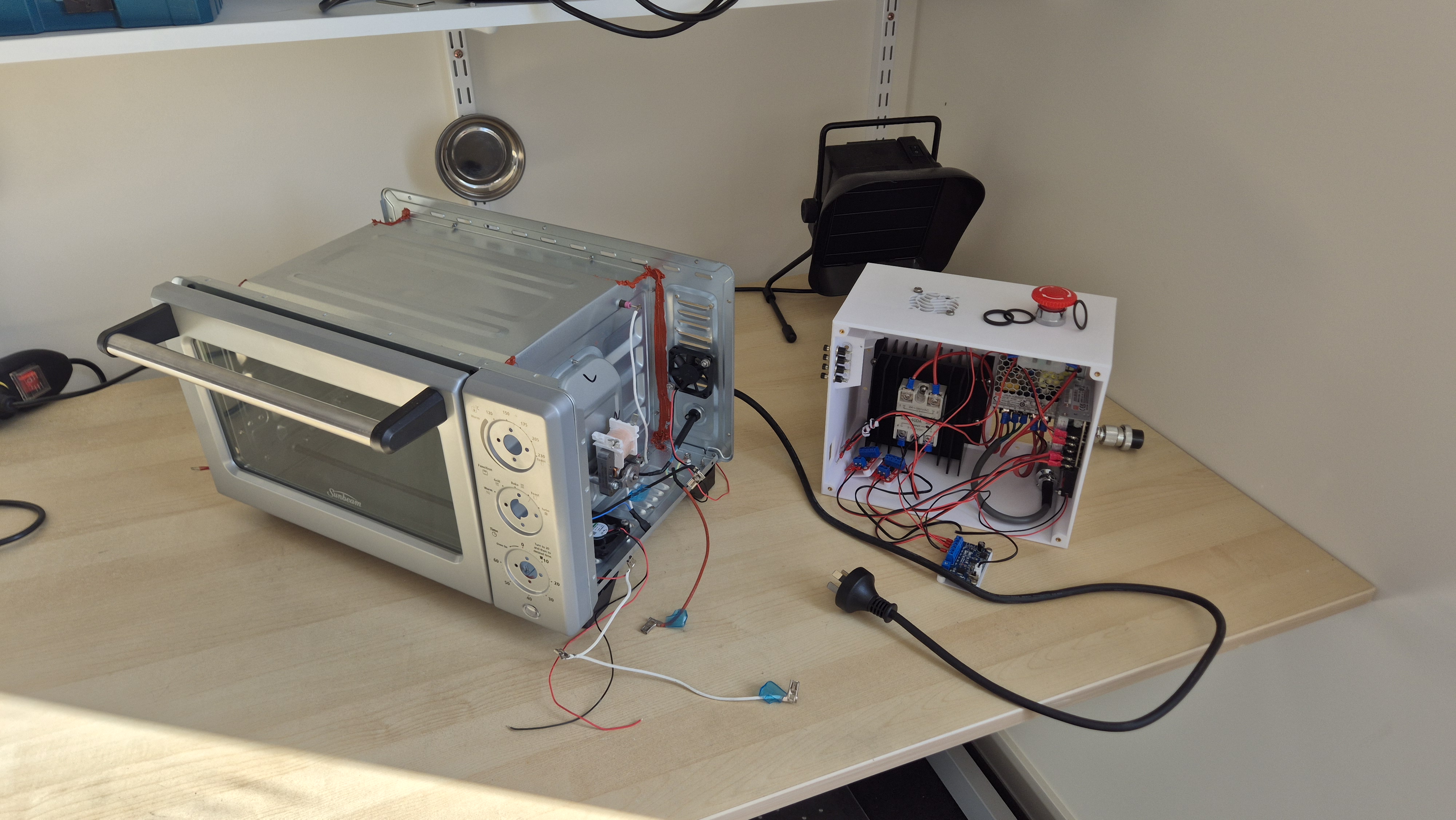

Building a reflow oven. To move beyond hand-soldering prototypes and into small production runs, I’m converting a toaster oven into a reflow station. This has taken longer than expected - one supplier sent the wrong parts (refunded), another shipment went missing entirely. Classic. But it’s coming together.

Current Blocker: Certification

Here’s the honest bit.

I recently tried to share the project in the Home Assistant Australia Facebook group and was (reasonably) told they couldn’t allow advertising for products that connect to mains power without proper compliance documentation.

Fair enough. But it raised the question: what does compliance look like for an aftermarket replacement PCB?

SwitchRoo is a low-voltage board that replaces the electronics inside an already-certified switch housing. The mains side isn’t changing. But Australian electrical compliance (EESS/RCM) isn’t straightforward for this kind of product, and I’m still working through what’s actually required.

If you have experience with Australian electrical compliance, RCM marking, or have navigated similar grey areas for aftermarket electronics, I’d genuinely appreciate your input. I’ve started a thread on the EEVblog forum here if you want the full technical discussion.

What’s Coming

Beyond getting boards populated and compliance sorted:

- Documentation site - proper docs with installation guides, wiring diagrams, and example ESPHome configurations like other projects in the ecosystem have

- Variant range - starting with SR-D1 through SR-D4 (1-4 gang Deta switches), with optional mmWave (e.g. SR-D3-MW)

Bigger Picture

Here’s what I’m excited about longer term: these off-the-shelf switch housings are everywhere. Electricians know how to install them. They fit standard wall boxes. They’re cheap.

Once you’ve got a low-voltage PCB platform that drops into that form factor, it’s not just a light switch anymore. It’s a standardised mounting point for any human interface you want around your home. Touchscreens. E-ink displays. Sensor panels. Room controllers. Whatever you can fit on a PCB.

Want to add a small control panel next to your existing light switches? Use the same housing, same installation process, different board. That’s the direction this could go.

Join the Community

I’ve set up a Discord server for anyone who wants to follow along more closely, ask questions, share ideas, or help out.

Whether you’ve got compliance advice, ESPHome expertise, or just want to chat about the project - come say hi.

That’s it for now. More updates as the reflow oven comes online and I start populating boards.

Cheers,

Sam.

Makerroo

Comments

Add a comment on Discord

New to our Discord? Join first, then look for the thread titled "MakerRoo: What We've Been Working On" in #blog-discussions. Then your comments will appear here!